In this SAP SCM tutorial, you will learn the step y step procedure to create Planned Order Creation in your SAP system with proper screenshots at every step.

What is Planned Order Creation?

A planned order in SAP is a procurement proposal that is created manually via t-code MD11 or created automatically using t-code CO40/CO41 while planning and then converted into a purchase requisition or a production order.

How to Create Planned Order Creation?

Please follow the steps below to create planned order creation:

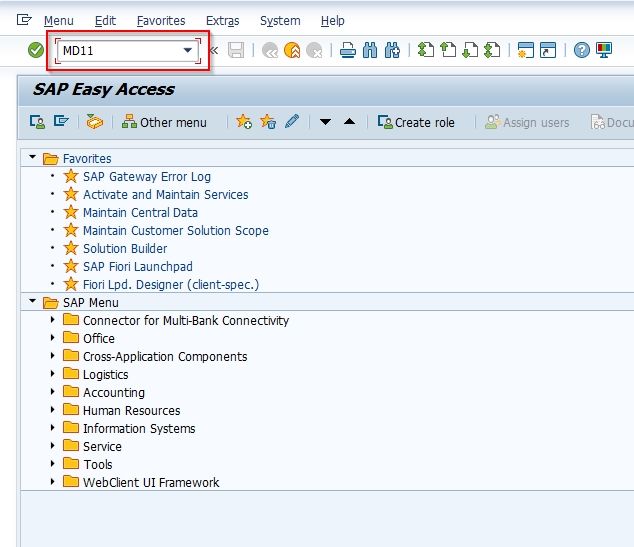

In the SAP Command field enter the t-code MD11 and press Enter to Execute it

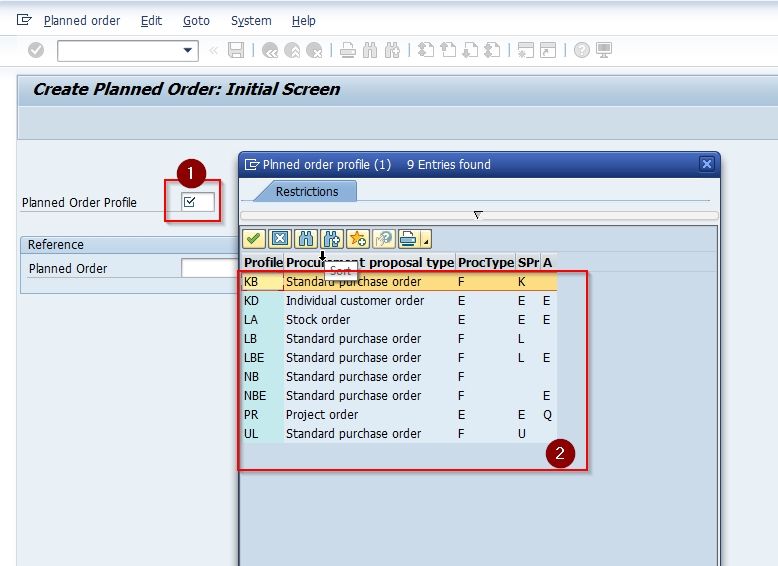

On the next screen select Planned Order Profile to choose the type of Planned order you want to create. There are multiple options to choose from as shown below.

In this example we choose Stock Order LA and press Enter to proceed

.jpg)

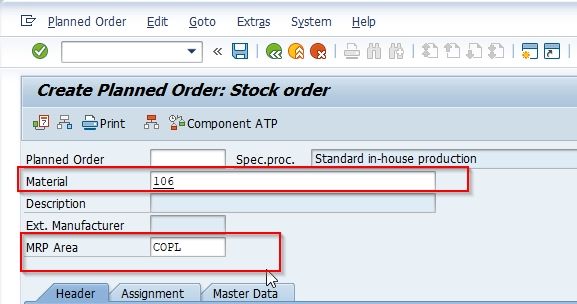

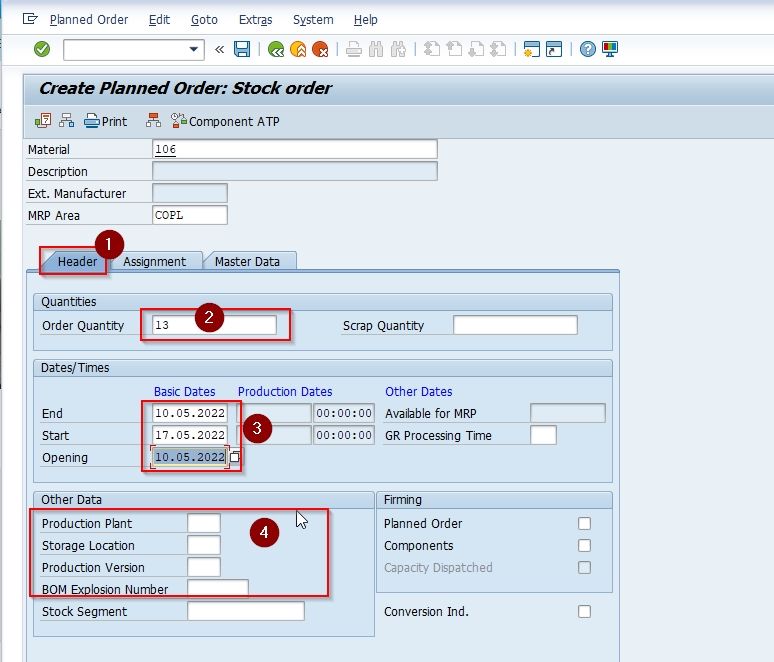

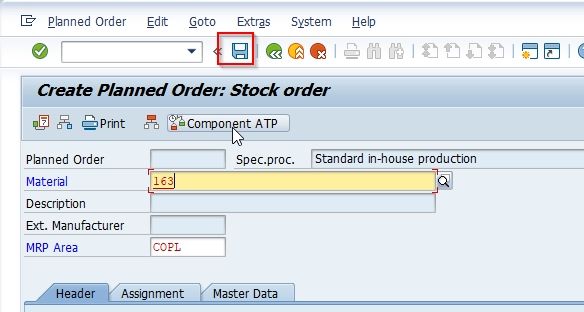

Next on Create Planned Order: Stock Order screen enter the following details

- Material

- MRP Area

Now under Header tab enter the following details

- Order Quantity

- Dates/Time

- Production Plant

- Storage location

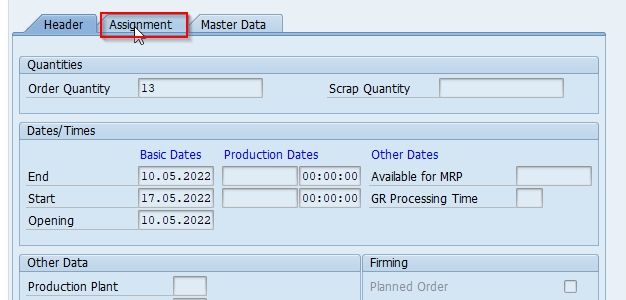

Now click the Assignment tab.

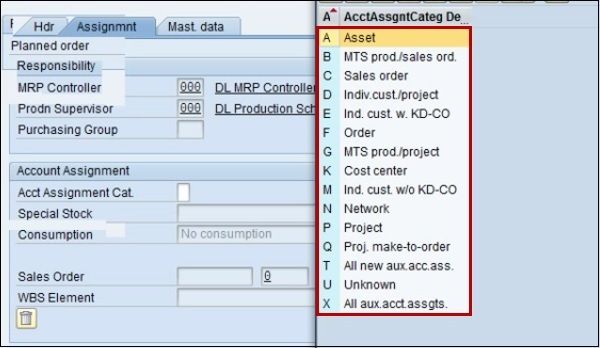

select the MRP Controller field to select the Controller option and choose Acct Assignment Category as shown in the image below

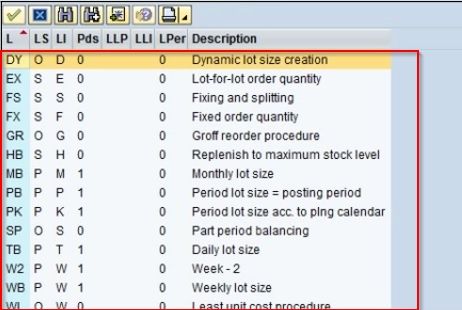

At last, go to the Master data tab and enter the lot size from the following option shown in the image below

Once all the details are entered click the Save button to save the new planned order.

You have successfully created a new planned order.

How to Navigate to Production order from Planned Order?

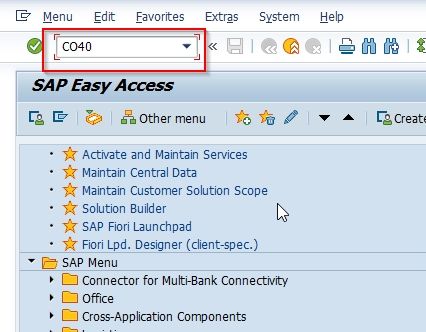

Please follow the steps below to navigate to Production order from Planned Order via t-code CO40:

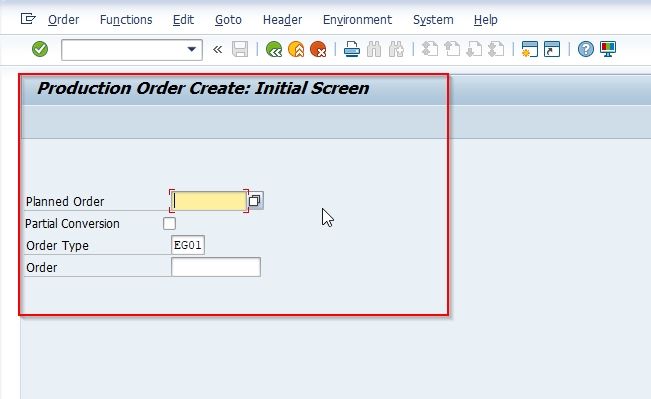

Execute t-code CO40 in SAP Command Field as shown in that image below

Now in the Production Order Create: Initial Screen enter the Order type to get their respective Production order.