In this SAP PP tutorial, we will learn the step-by-step process of performing capacity planning in SAP with proper screenshots.

What is Capacity Planning?

Capacity planning in SAP is a process that is done in order to balance the load at the work center. A user can calculate the production capacity based on the requirement of the product according to the available capacity.

An SAP user needs to check the capacity load on the work center. If in case any work center is overloaded, then the user needs to move the orders to different work centers.

How to Check Capacity Loads?

Please follow the steps below to check the capacity load:

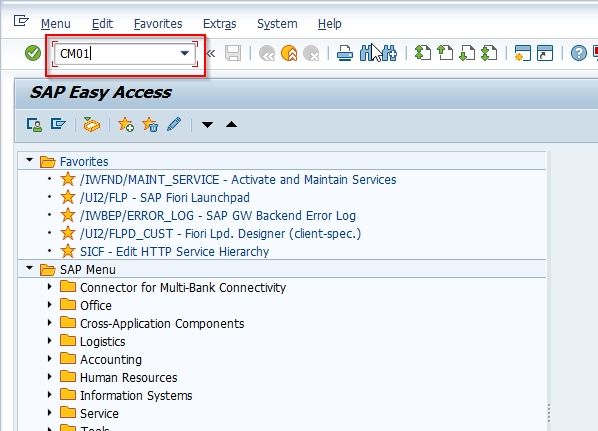

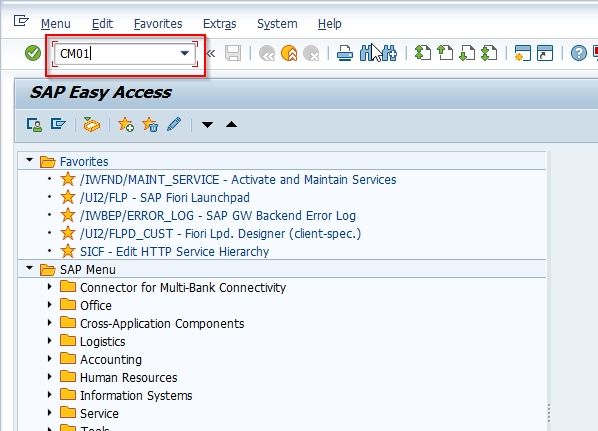

Execute t-code CM01 in the SAP Command field

OR

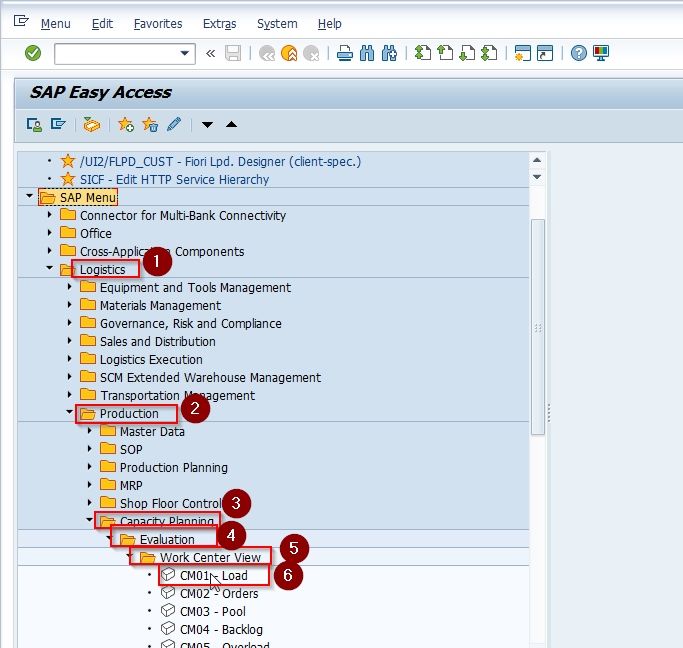

Follow the below IMG Path

Logistics → Production → Capacity Planning → Evaluation → Work Center View → Load

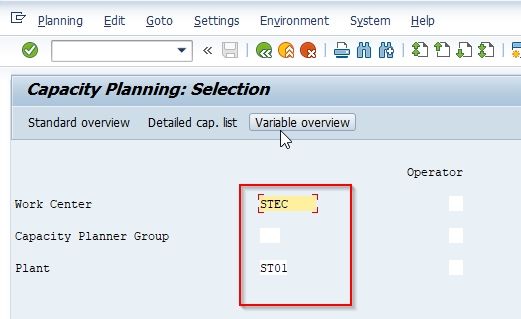

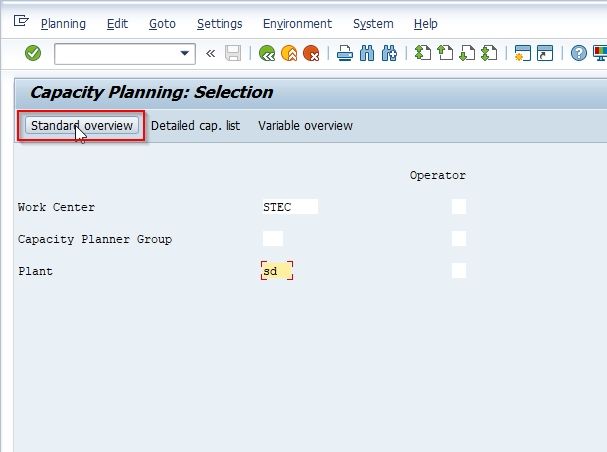

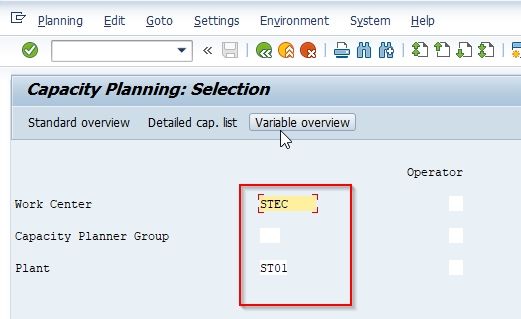

Next on the Capacity Planning screen enter the following details

- Work Center

- Plant

Now click the Standard View button.

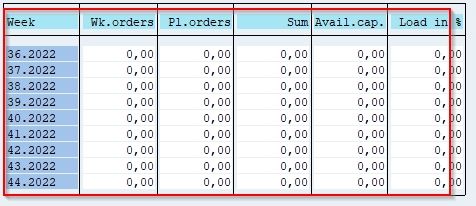

On the next screen, the SAP user will be able to see the following:

- Capacity requirement

- Available capacity

- The workload

- Remaining available capacity

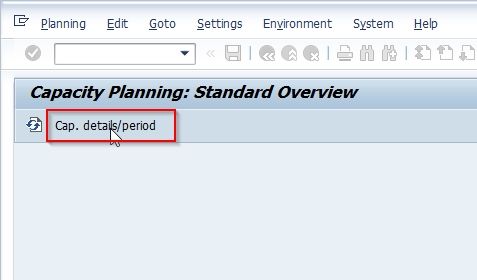

Here the user can choose a particular week and click the Cap. Details /Period. The SAP user will the detailed load elements at an individual level.

How to Check Planned Orders and Production Order Details?

Please follow the steps below to check the planned orders and production order details:

Execute t-code CM01 in the SAP Command field

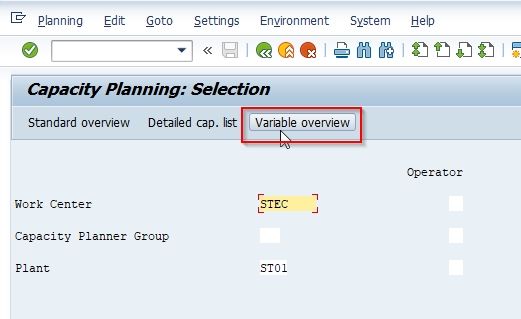

Now on the Capacity Planning screen enter the Work Center and Plant details

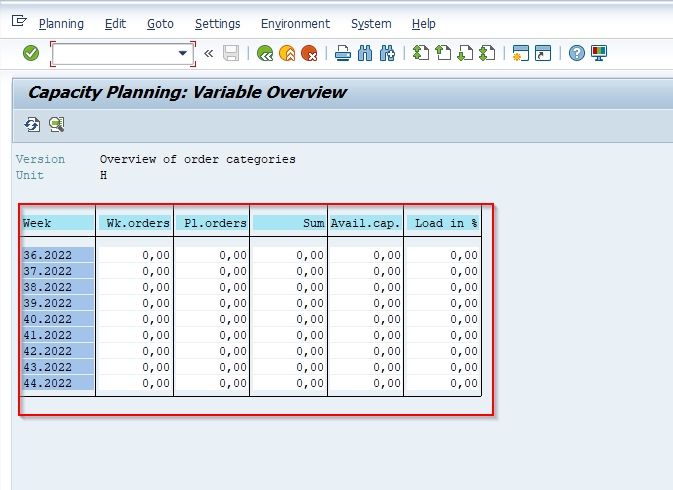

Next, click the Variable Overview button.

On the next screen you will see the Capacity Planning Variable details.