For SAP PP consultants, it is very important to understand the concept of SAP workcenters as well as routings in SAP.

What is Routing in SAP PP?

Routing in SAP PP (Production Planning) refers to the process of defining the steps, sequences, and resources required to produce a material or a product. It is a key component of the SAP PP module and is used to plan and control the production process in a manufacturing environment.

Routing in SAP PP typically involves the following steps:

- Defining the manufacturing process: This involves breaking down the production process into individual steps or operations. Each operation is assigned a unique operation number, description, and duration.

- Defining the sequence of operations: Once the operations have been defined, they are sequenced in the order in which they must be performed to produce the material or product. The sequence is based on the dependencies between the operations and the overall production process.

- Assigning resources: Resources such as machines, tools, and labor are assigned to each operation. This helps to determine the capacity required for each operation and the overall production process.

- Defining work centers: Work centers are defined for each operation. They represent physical locations where the production process takes place and are used to track the progress of the production process.

- Defining production versions: A production version is created for each material or product. It contains routing information and other production-related data.

Characteristics of Routing

- Routing is an essential part of production planning.

- Routings specify the sequence of operations that need to be carried out.

- Routings also contain important product information, such as work location, the time required, and necessary materials and equipment.

- A specialized selection procedure is used to choose the correct routing based on the type of work order.

How to Define Routing in SAP?

Please follow the steps below to define routing in SAP:

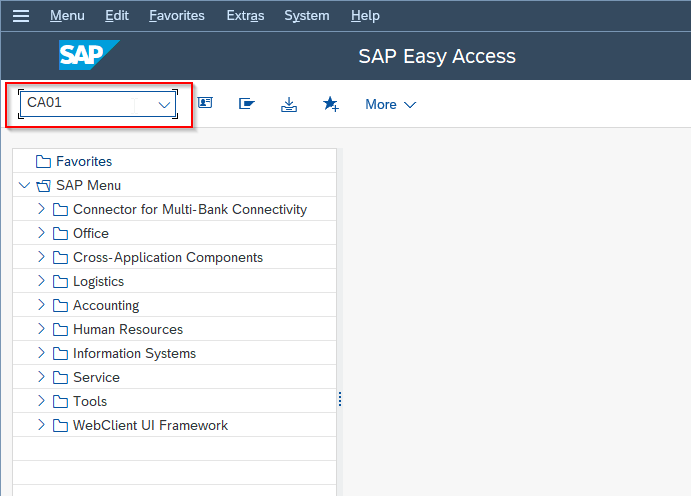

Execute t-code CA01 in the SAP command field.

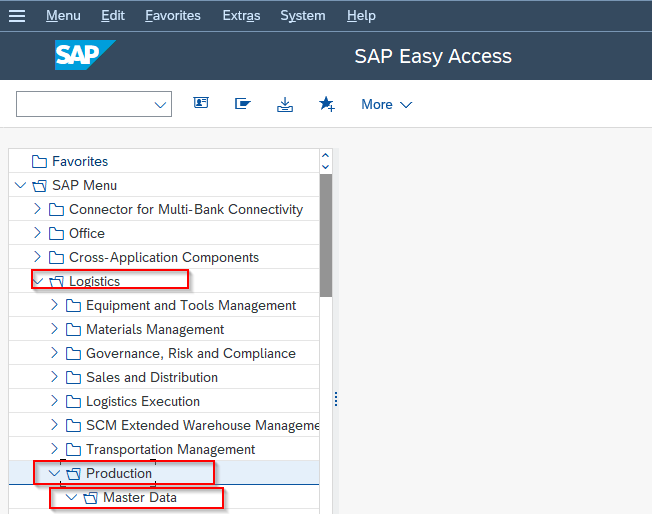

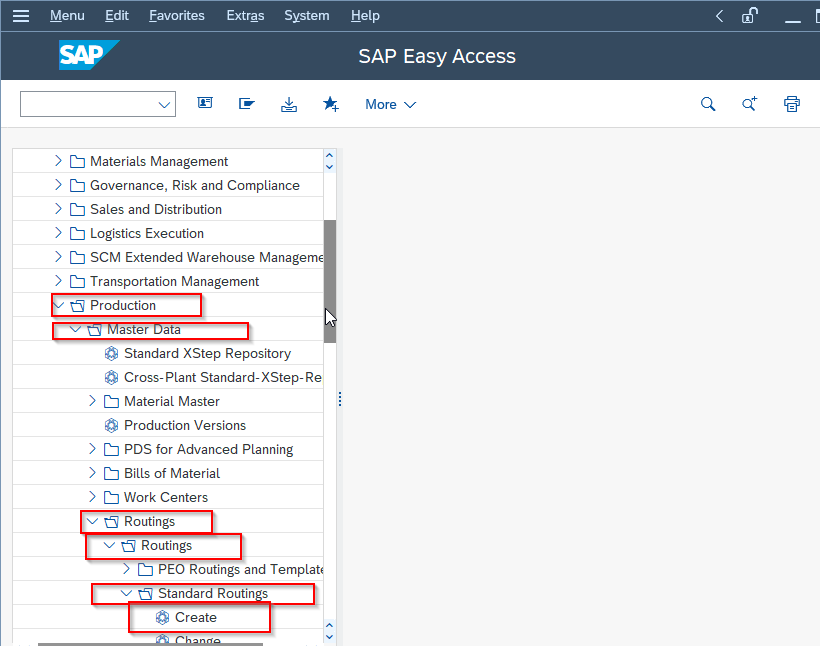

or Navigate to follow the SAP IMG path:

Logistics → Production → Master Data → Routings → Routings → Standard Routings → Create

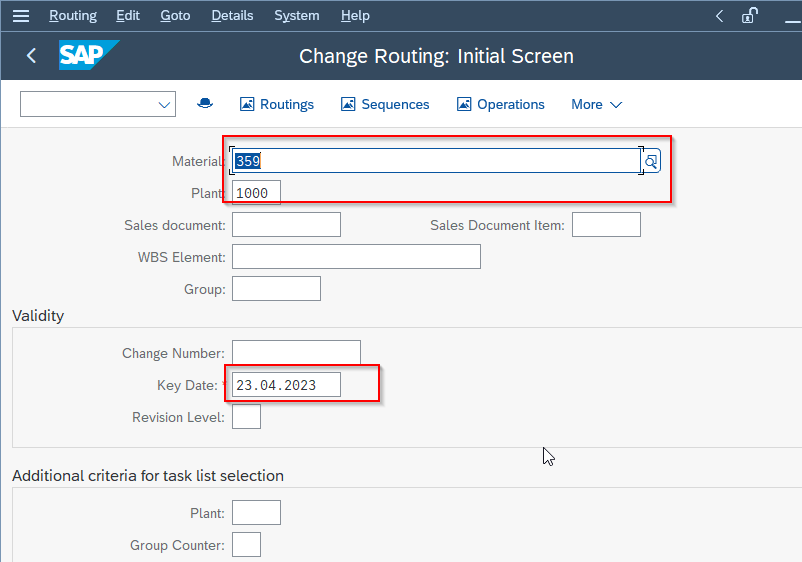

Next on Create Routing: Initial Screen enter the following details:

- Material for which routing needs to be defined

- Plant Code

- Routing validity date as a key date

Click on the Continue button to proceed.

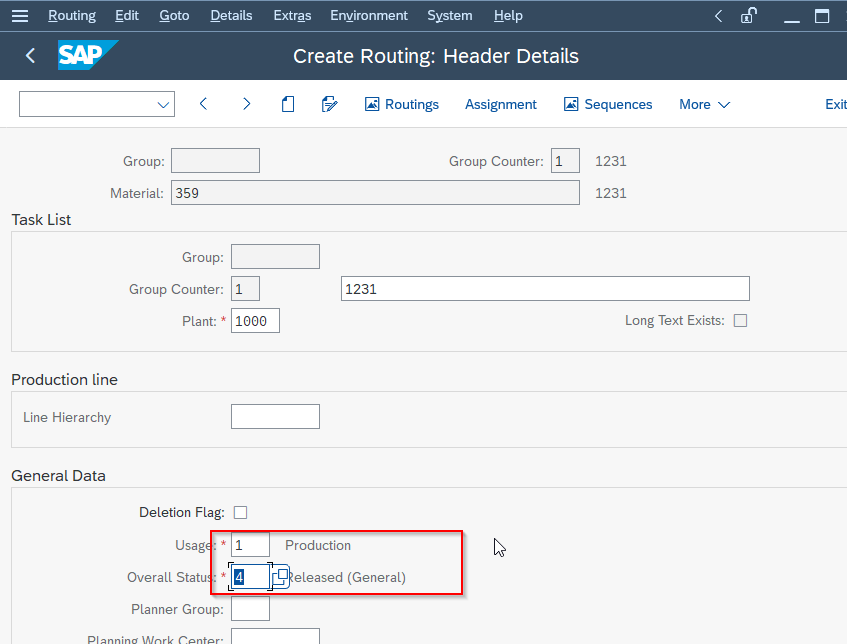

Now on Creat ROuting: Header Details under General data enter the following details:

- Usage as 1: Production routing and will be used in Production Order.

- Select Status as 4 shows the released status. It indicates that routing is valid for material requirement planning and costing.

- Mention the Lot Size 9999999, which means that routing is valid for order quantity between 0 and 9999999.

an go to

an go to

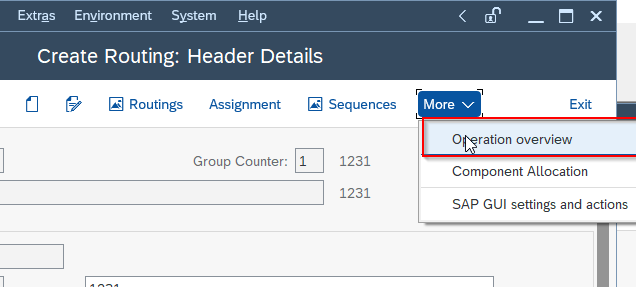

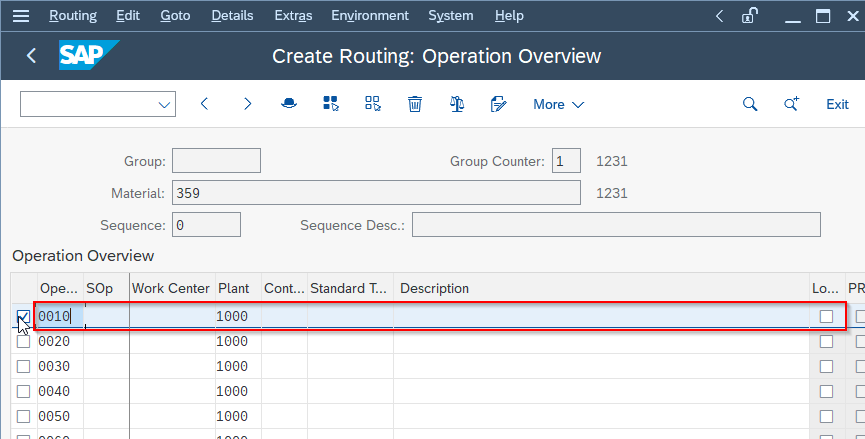

Now go to More > Operation overview button to add the sequence of operation.

Now to maintain Operation data:

- Enter the Work Center code.

- Select Input Control Key to determine the operation to be scheduled, costed, etc.

- Enter the base quantity and set up time in minutes for base quantity.

- Enter machine time in minutes for base quantity.

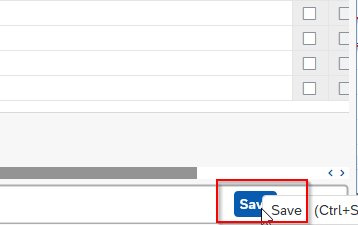

Now once all the field are entered click on Save button.

You will get a confirmation message on the bottom of your screen that routing is saved.

What is Work Center in SAP PP?

A work center in SAP PP is a physical location where production activities take place. It can be a machine, a group of machines, or a specific area in a factory where work is performed.

Work centers play a critical role in production planning and control as they determine the capacity and availability of resources needed for production.

Characteristics of Work Centre

- Work centers are a critical component of production planning in SAP.

- A work center refers to a specific location where a production operation takes place.

- Work centers are used in both production task lists and production orders.

- Work centers can be used as capacity collectors for both internal and external processing.

- Work centers are the location where production resources are consumed by manufacturing and production activities.

How to Create Work Center in SAP PP?

Please follow the steps below to define work center in SAP:

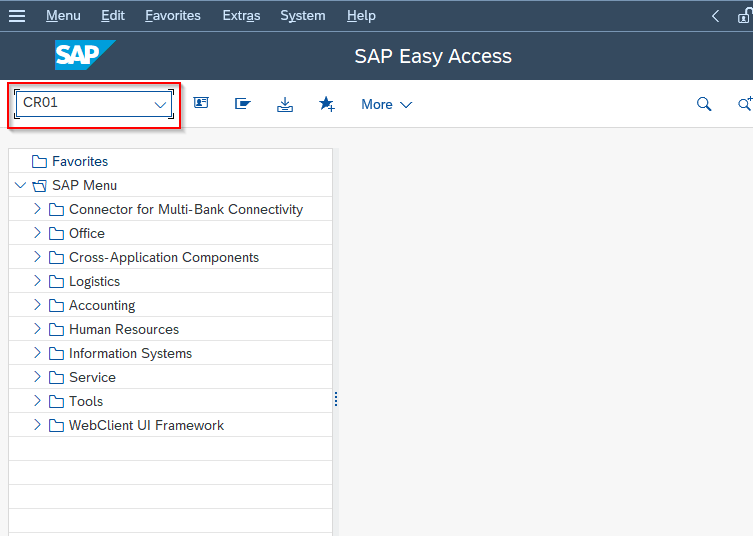

Execute t-code CR01 in the SAP command field.

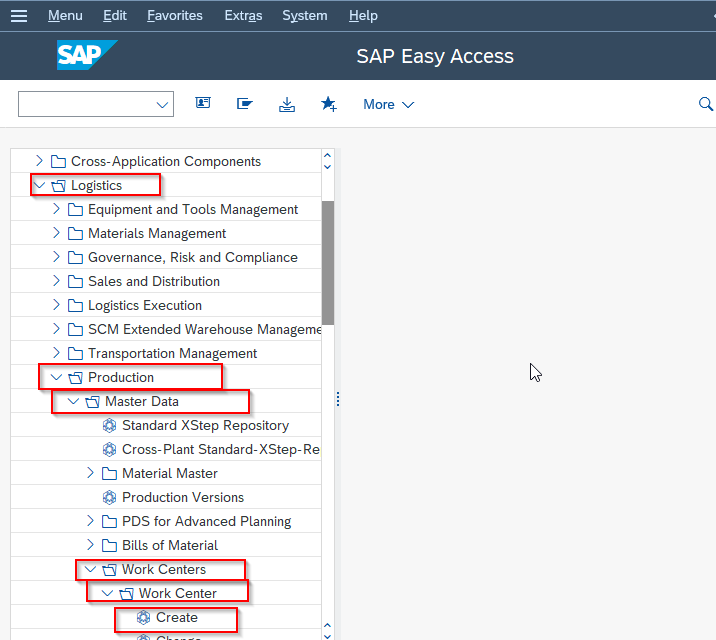

or Navigate to follow the SAP IMG path:

Logistics → Production → Master Data → Work Centers → Work Center → Create

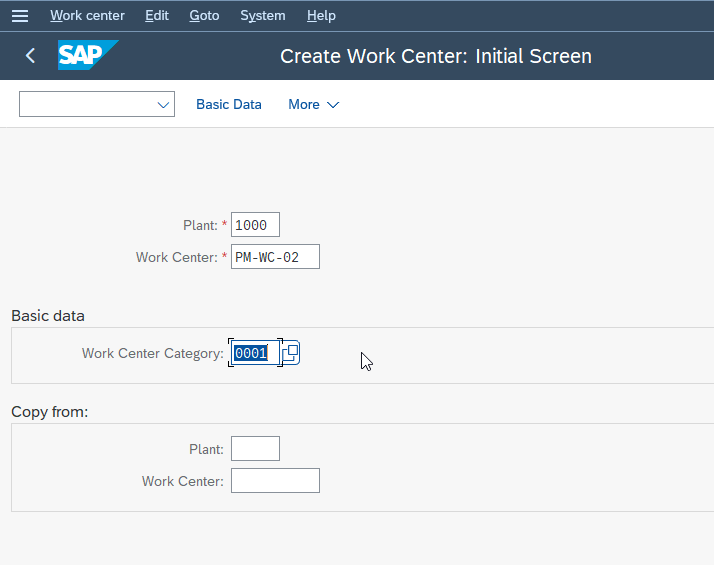

Next on Create Work Center: Initial Screen enter the following details:

- Name of the work center name

- Plant name where the work center is located

- Select the Work Center Category

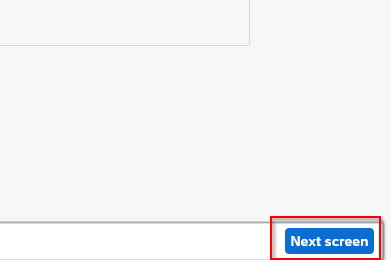

Click on the Next screen button

Nowon Create Work Center: Basic Data enter the following details −

- Work Center description.

- Person responsible for code for that work center.

- Physical location where the work enters is located in the plant.

- Enter usage

- Enter the Standard Value key

.png)

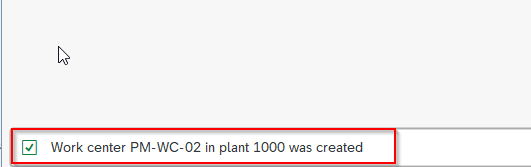

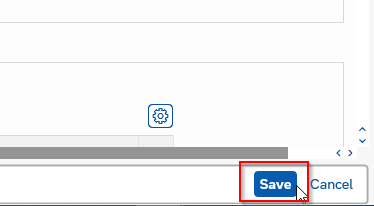

Once all fields are entered click on Save button to save the new work center

You have successfully created a new work center