What is SAP MM?SAP MM Training Tutorials for BeginnersSAP Master Data SAP MM Valuation ClassSAP MM Tree MenuSAP MM Split ValuationWhat is MRP in SAP MMSAP Reverse Material document SAP MM Process FlowSAP MM Movement Types SAP Vendor ListDelete Material in SAPSAP MM Release StrategySAP MM Accounting EntriesSAP MM Pricing ProcedureSAP MM Transaction CodesSAP MM Certification Cost in IndiaSAP MM Consultant Salary & Job ProfileSAP MM Interview Questions

Tutorials

- What is SAP MM?

- SAP MM Training Tutorials for Beginners

- SAP Master Data

- SAP MM Valuation Class

- SAP MM Tree Menu

- SAP MM Split Valuation

- What is MRP in SAP MM

- SAP Reverse Material document

- SAP MM Process Flow

- SAP MM Movement Types

- SAP Vendor List

- Delete Material in SAP

- SAP MM Release Strategy

- SAP MM Accounting Entries

- SAP MM Pricing Procedure

- SAP MM Transaction Codes

- SAP MM Certification Cost in India

- SAP MM Consultant Salary & Job Profile

- SAP MM Interview Questions

MM (Materials Management) Tutorial

- Stock/valuation data of previous periods

Stock and valuation fields that refer to the previous period or those dating back even farther, are not stored in those tables in which the current st ... - Difference between the Availability Check 01 and 02

Availbility check 01 (Daily requirement) vs 02 (Individual Requirement) in SAP MM 01 and 02 are the checking group. Availability check is carried o ... - Mass Change MRP Indicator

When you change the MRP indicator ( transaction SM30 - V_T001L_D ), SAP does not mass update all the material Sloc MRP Indicator in MRP View 4. It ass ... - Production version selection when converting planned order

I am using multiple production versions in the material master for a combination of different alternative BOMs & Routing Group counters. In the IMG (O ... - SAP LO Logistics tcodes Common Use Transaction Codes

VS00 - Master Data; VC00 - Sales support; VA00 - Sales; VL00 - Shipping; VF00 - Billing. VD01 - Create customer master; VD02 - Change cu ... - Work Scheduling View in Material Master

What is the importance of work scheduling view in material master and the standard values in Routing? If I am maintaining Lot size dependent infor ... - BAdI implementation for append fields in mass maintenance MM17

Prerequisite for the implementation of customer-specific append fields in mass maintenance MM17: The system must be able to process the customer-sp ... - Qualifications and Skills requires to become a MM Consultant

Eligibility for SAP MM This course can be pursued by any professional with a basic university degree like BA, BBA, BSc, MBA, Engineering, MTech etc ... - Settlement transaction types

SAP appears to be inconsistent with their usage of transaction types as it relates to AuC's and project system. To create a settlement rule we us ... - Fields selection for MB51 - RM07DOCS

You can enhance MB51 by reconfiguring the fields contained in the field catalog. IMG -> Material Management -> Inventory Management and Physical I ... - Table Mass Change

In the Mass change function itself: You are in the selection screen for mass changes. You have maintained the selection criteria for the required pr ... - Why Expected value mandatory in service POs with limits

The expected value has to be mandatory in case only limits are maintained in a purchasing document. The former system design was not correct, because ... - Difference Between Client , Purchasing Org , Plant , Company code

What is the technical difference between Client , Purchasing Org , Plant , Company code? Client : Unit within SAP system, self-contained, separate ... - Vendor Discount Condition

We have cetain vendors for whom the discounts need to be calculated automatically at the time of outgoing invoice payment. Transaction MEKE is used f ... - Difference between the transactions ME25 and ME21N

Transactions ME25 Vs. ME21NME25 is useful when you want to create a PO but you are unsure if there is a valid source or if there is, which one to use. ... - Purch.Order with two different Payment Vendors

I am working ECC6. I create a PO for a Vendor with Freight Conditions with estimated costs. The PO has Release Strategy that once released for GR it c ... - Convert Planned Orders to Purchase requisitions and Purchase Orders

We can create planned orders & convert them into purchase requisition or into production order. In the material master ,MRP2 view give the proc ... - How can we restrict the automatic bar code request pop up in MIGO?

We want to restrict the automatic bar code request pop up to specific company codes or plants, either through customizing or user exists.You can see t ... - Business area in the vendor item

When you create invoices in the invoice verification, the business area is not always copied from the offsetting entries in the vendor item. This is ... - Price differences during GR for production order

Problem You post a goods receipt for the production order. During posting, price differences are created although the standard price of the materia ... - Adopt Purchase Order Header Text

To default the Header Text into the Purchase Order Step 1 :- Maintain text in Vendor Master MK02 - Change Vendor Choose Extras -> Texts - In ... - Inspection Lot in Inventory Movement

Inspection Lot at 103 movementCan movement type 103 ( receive to GR block) create inspection lot ?Is result recording possible for this lot?Yes it is ... - Quota Arrangement Setup

To set up a quota arrangement for the procurement of a material, proceed as follows: Master data -> Quota arrangement -> Maintain, ente ... - MM - Controlling the Fields in Material Master

Define whether a field is hidden or displayed, or whether an entry is mandatory or optional in material master maintenance by assigning the field to a ... - Conditions with several validity periods

During the maintenance of the conditions of an info record or a purchasing document (in case of which 'time-dependent conditions' are set in t ... - No shelf life expiration date or a date of production dialog box appear during automatic batch determination.

You must enter a shelf life expiration date or a date of production when you post an automatic goods receipt of a material to be handled in batches wi ... - Valuation Class for Material Group without Material Master

In 4.6x, you can assign valuation class to Material Group. It is useful in the sense that user do not have to manually do an Account Assignments. ...  Resize or Enlarge Document Overview in Transaction ME*N

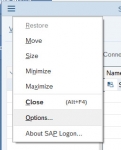

Resize or Enlarge Document Overview in Transaction ME*N

How to Resize or Enlarge Document Overview in Transaction ME*N ? All transaction related to ME*N like (ME21N, ME22N, ME51N, ME52N, ME53N) has a com ...- How to create and attach inward gate entry to a purchase order?

Gate Entry keep track of the entry and exit of the goods to and from the warehouse. There are 2 types of Gate Entry Inward and Outwad. Procedure to ... - How to maintain relation between Alternatives Materials in SAP.

How to maintain the relation between the alternatives in SAP? How the MRP considers the quantity of each alternative for the MRP calculation? You c ...

×